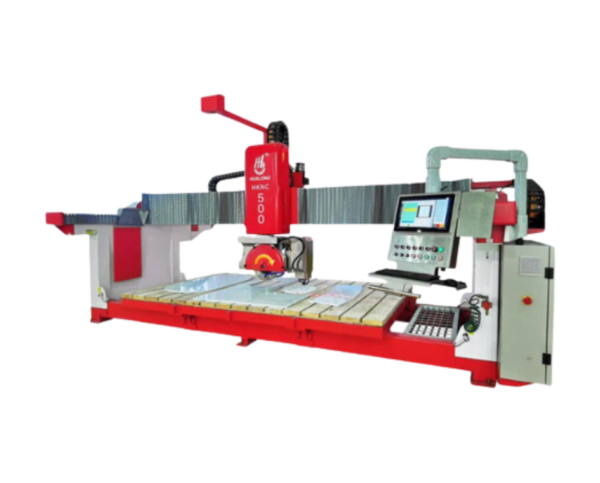

5 Axis CNC Bridge Saw Stone Slab Cutting Machine

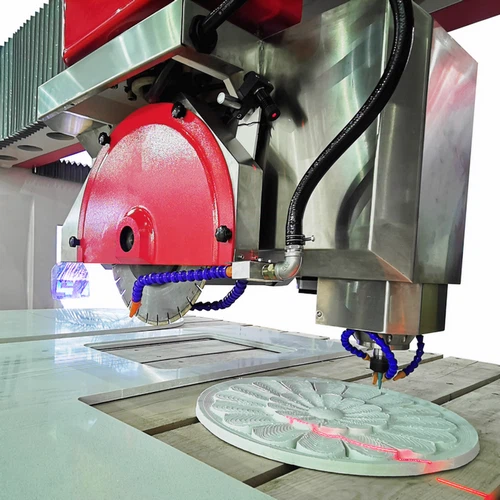

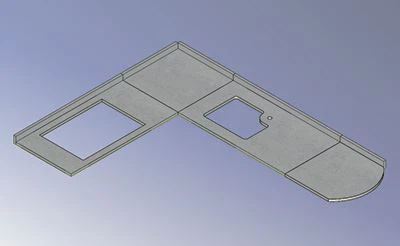

Bridge type stone cutting machine HKNC-500, equipped with Italy CNC system ESA and 5 axis interpolation, is applicable for cutting all kind of stone slabs to size, such as granite, marble, quartzite and artifical stone slab etc. It combines fuctions of carving, milling, cutting, drilling, engraving into an organic whole for complex countertops processing.

* Contact us for latest price for customized machine according to your project’s requirements of table formats, functions, etc.

Features

- With Vacuum lifter for moving slab (optional)

- Table size: 3300*2000mm

- Italian ESA operation system and Italian Pegasus CAD CAM drawing software

- With office software for CAD CAM drawing at home or in office and 3D cutting (optional)

- Monobloc structure bridge saw will be easy for installation and loaded inside 20 foot container as a whole.

- Connection method: 1/2G

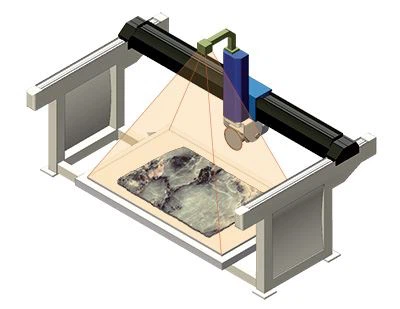

- Photo camera digitizer for slab positioning and typesetting to optimize slab usage.

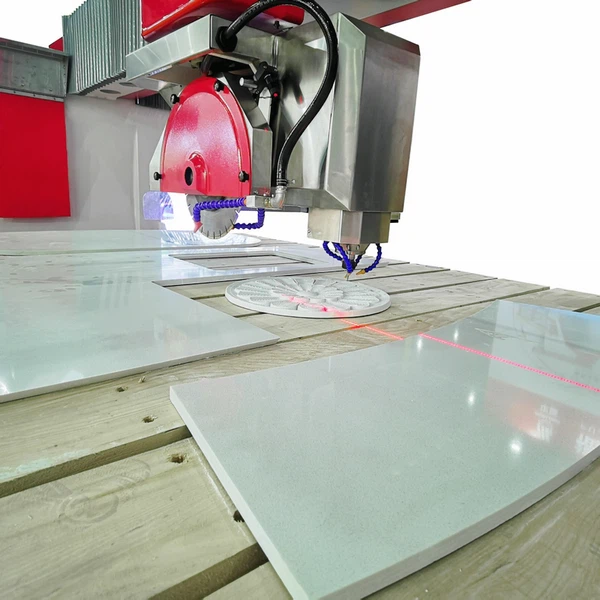

- Laser marker and Steel structure

- 0°/45°/90° head tilting, 360° head rotation. 0° to 85° table tilting, automatic rotation at every 45° degree and 0° to 360° table rotation at any degree manually.

- Taiwan Hiwin Linear guide in X and Y axis and Hiwin ball screw in Z axis

- Helical rack and pinion in X and Y axis

- Italian ESA Driver, Italian ESA Controller and ESA servo motor and Savch inverter

- Manual and automatic lubrication

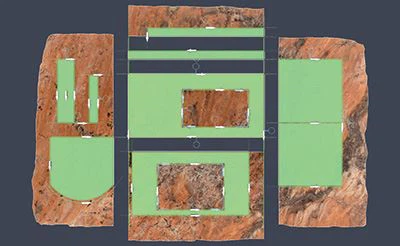

SLAB IMAGE CAPTURE

The application allows to acquire and process the slab photo, by correcting the lens distortion and rectifying it. Through the acquired image, the shapes can be arranged on the slab avoiding material imperfections while identifying the nervures that need to be machined; it is also possible to qualify the slab edge geometrically.

DRAWING AND DESIGN

It is possible to define the shapes being machined:with 2D CAD tools/by importing a DXF/DWG file

with the automatic acquisition from a photo (using the photo-digitizer module)by importing a list from a proprietary format: Excel, CSV

The shapes begin machined will be grouped in an itemized list.

SHAPES POSITIONING

The shapes can be arranged on the slab both with manual and automatic nesting. The shapes being nested are loaded from the active itemized list.

SOFTWARE FUNCTIONALITIES

Slab cutting handling

CAD 2D tools

Manual/automatic Nesting

Calculation of optimized trajectories for the disk cutting

Automatic rest machining to complete the cuts using a cut-drill/mill tool or a waterjet tool

Movement of the slab pieces through the suction cups manipulator.

Parameters

TECHNICAL DATA FOR HKNC-500 | ||

Diameter of saw blade | ø400-ø500 | mm |

Dimension of working platform | 3300×2000 | mm |

Max. cutting length | 3300 | mm |

Max. cutting thickness | 140 | mm |

Max. lifting stroke | 250 | mm |

Max. lifting weight by sunction cups | 200 | kg |

Power of main motor | 11 | kw |

Power of cutter frame reciproctating motor | 2 | kw |

Power of crossbeam shifting motor | 1.1 | kw |

Power of hydraulic station motor | 2.2 | kw |

Power of lifting motor | 0.85 | kw |

Gross power | 16 | kw |

Water consumption | 2 | m3/h |

Gross weight | 5400 | kg |

Dimensions (L x W x H) | 5700x3260x2765 | mm |