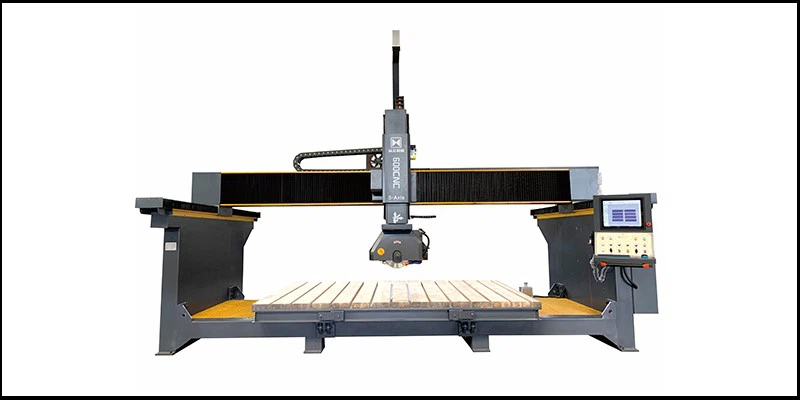

5+1 Axis Bridge Saw ZLBS-600CNC/5+1A

We supply 5 Axis CNC Bridge Saw, Type: ZLBS-600CNC/5A(Heavy-duty), ZLBS-600CNC/5+1A(Heavy-duty), for processing marble, granite, quartz stone, ceramic, porcelain, and other materials. 5 Axis CNC Bridge Saw is a fully Automatic Stone Cutting Machine, after taking a picture and program to the system, the machinery will start working automatically. It adopts CNC control system, which can realize manual programming or automatic programming with ease.

* Contact us for latest price for customized machine according to your project’s requirements of table formats, functions, etc.

Features

We supply 5 Axis CNC Bridge Saw, Type: ZLBS-600CNC/5A(Heavy-duty), ZLBS-600CNC/5+1A(Heavy-duty), for processing marble, granite, quartz stone, ceramic, porcelain, and other materials. 5 Axis CNC Bridge Saw is a fully Automatic Stone Cutting Machine, after taking a picture and program to the system, the machinery will start working automatically. It adopts CNC control system, which can realize manual programming or automatic programming with ease. It can easily perform Transversal Cuts, Longitudinal Cuts, Orthogonal Cuts, arc Cuts, Circle Cuts, concave-convex Shaping,etc., is a necessary stone machine for stone processing factories. Italian System is optional.

Parameters

Model | ZLBS-600CNC/5A(Heavy-duty) | ZLBS-600CNC/5+1A(Heavy-duty) |

Worktable size | L3500mm*W2000mm | L3500mm*W2000 |

Maximum Processing | L3500mm*W2000mm*H500mm | L3500mm*W2000mm*H500mm |

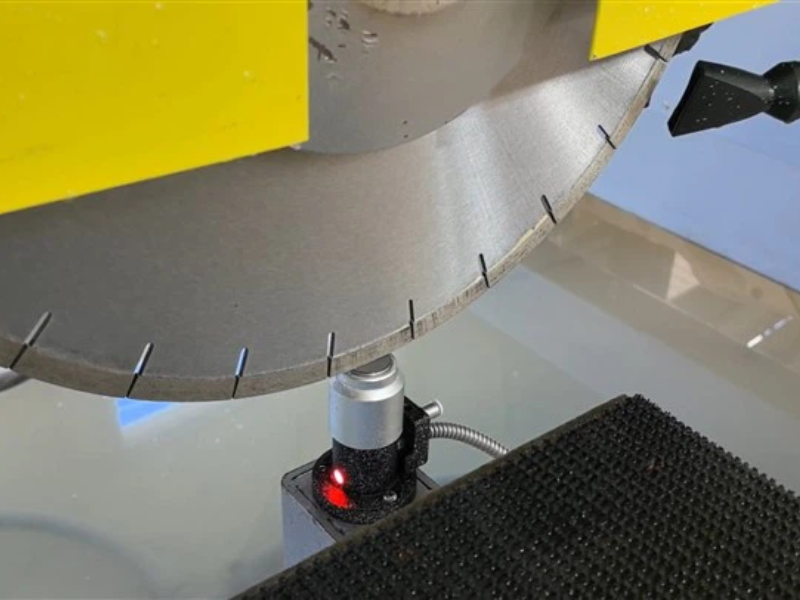

Blade External Diameter | ₵350-620mm | ₵350-620mm |

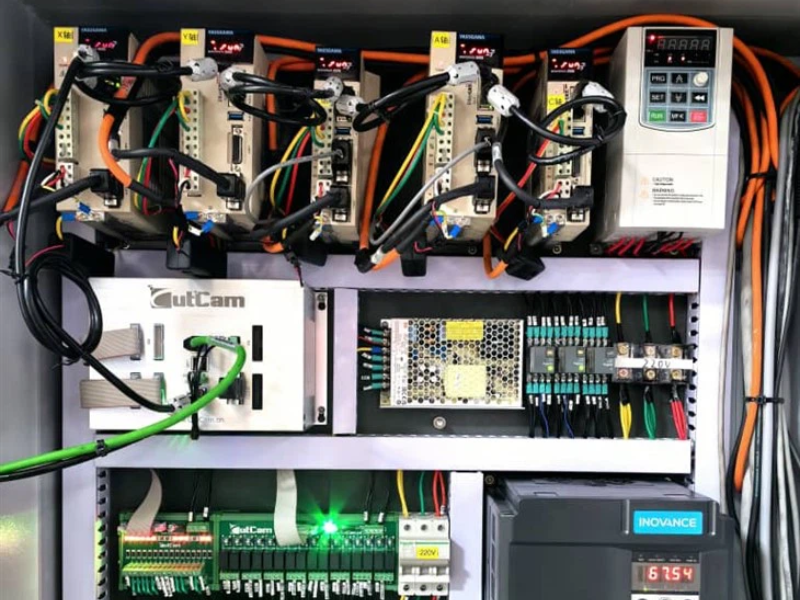

Control center | An Industry computer with CNC System | An Industry computer with CNC System |

Driving motor | Servo motor | Servo motor |

Main motor power | 22kw (permanet magnet motor with frequency) | 22kw (permanet magnet motor with frequency) |

Main Motor Spindle type | Can be put a drill | Can be put a drill |

| Electric Spindle | / | Rotating speed: 0-24000 rpm It’s for Faucet-hole-drilling, inner corner milling etc. for Worktops, Vanity Tops… |

Total power | 30kw | 35kw |

| X,Y, Z-axis Guide Rail | Y axis, Z axis: Heavy Duty #35 Guide Rail for heavy loads X axis: #30 Qulity Guide Rail | Y axis, Z axis: Heavy Duty #35 Guide Rail for heavy loads X axis: #30 Qulity Guide Rail |

C-axis Rotate | 0°~360° | 0°~360° |

A-axis Rotate | 0°~90° | 0°~90° |

worktable flip | 85° | 85° |

| Side Beams | Welding Steel with 3 layers Metallic Paint (Welding Steel can be better processed by high-precision machine tool, and 3 layers Metallic Paint can avoid machine from rusting) | Welding Steel with 3 layers Metallic Paint (Welding Steel can be better processed by high-precision machine tool, and 3 layers Metallic Paint can avoid machine from rusting) |

Water consumption | 2m³/h | 2m³/ h |

Total weight | 6 tons | 6 tons |

Dimensions | L5750mm*W3750mm*H4000mm | L5750mm*W3750mm*H4000mm |

Delivered dimensions | L5750mmxW2200mmxH2600mm | L5750mmxW2200mmxH2600mm |

| ||

Features

#35 Guide Rail

It is a heavy-duty machine. It adopts #35 Guide Rail for Y axis and Z axis, enables production for maximum 17cm Granite slabs. (For processing Thick granite slabs, 35mm Guide Rail is a safer choice, which ensures the long lifetime of the machine. ) It's a one-piece Machine, easy to install and move, and takes up less space.

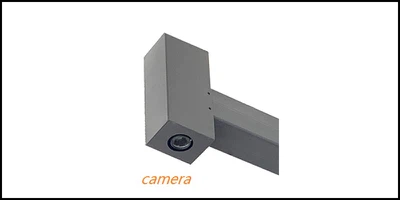

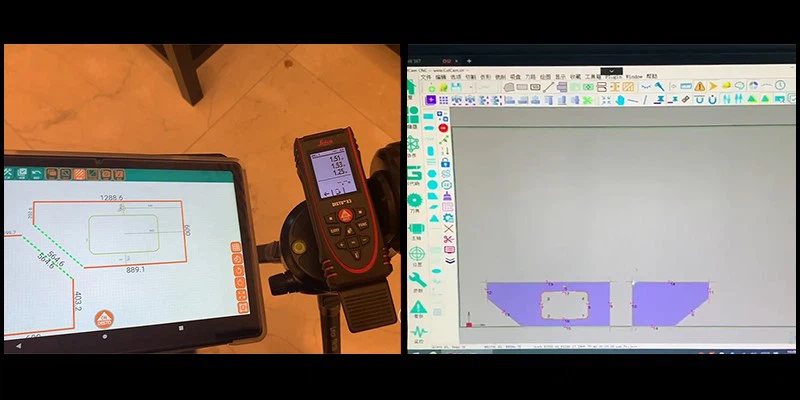

With A Camera to Locate the Position

This Machine equipt a high-precision camera to locate the position of the plate and show the cutting procedure. The machine is equipped measuring probe for thickness, together With the image caught by the camera, the machine can calculate the size of the slabs automatically. It saves human labour and increase working efficiency.

Worktable Turnover 85°

This worktable can be turned over 85° for easy loading stones.

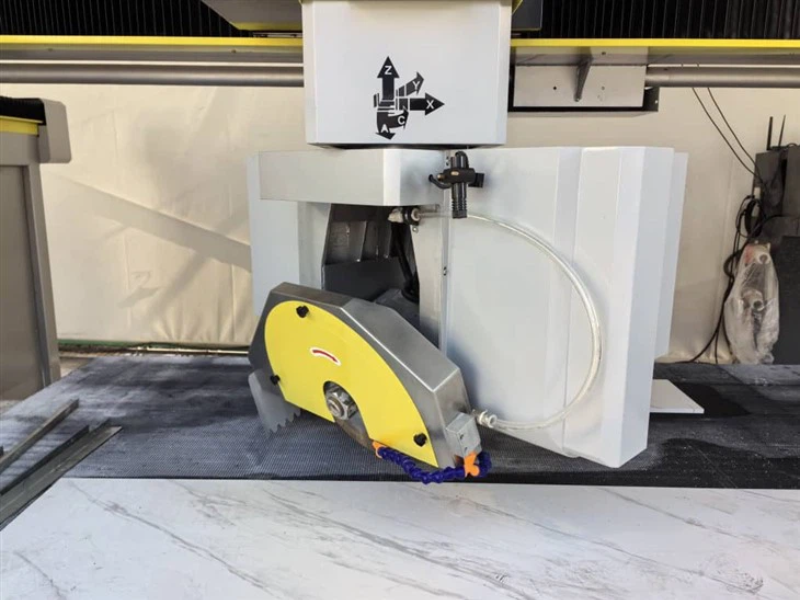

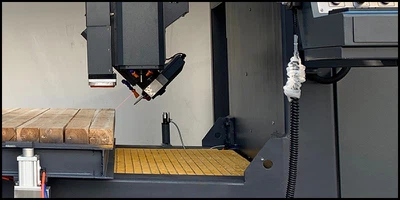

Machine Head tilt 0°-90°, rotate 0°-360°

The A axis can automatically rotate 0~90°, while the C axis can automatically rotate 0~360°.

Four-Side Chamfering

This machine can do four-side chamfering, with Maximum chamfering size: 3500x2000mm. Even big size slabs can be processed easily.

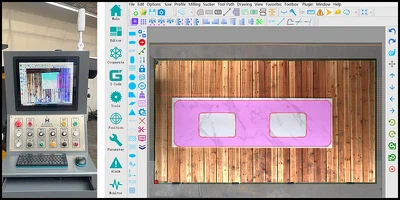

With 17" Color Touch-Screen

This Machine has an industrial computer and a 17" color touch-screen. Operators can process various forms of chamfering and 3D shaping, such as arc line shaping and wave line shaping , with the function of photo layout.

With CNC System and a Built-in Library

CutCam CNC System has a built-in drawing library of conventional shapes, supporting data input, and DXF format Files. The computer host comes with CAD drawing software.

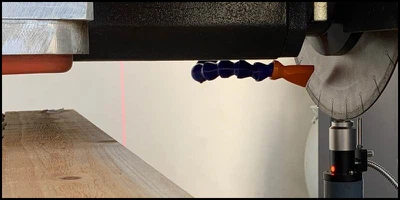

With Automatic Tool Setting Gauge

An automatic tool setting gauge is equipped that automatically checks the blade. It ensures high-precision Production.

With Suction Cups

This machine can work out the best cutting solutions according to the design drawings. If the cutting paths conflicts with each other, the suction cups can help to move slabs automatically. It enables complete automatic Production.

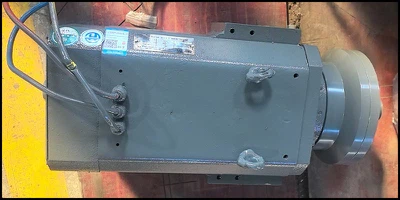

With CNC System and a Built-in Library

This Machine has a 22kw Permanent Magnet Motor It can automatically adjust the output power, strength, and is power-saving and environmental friendly.

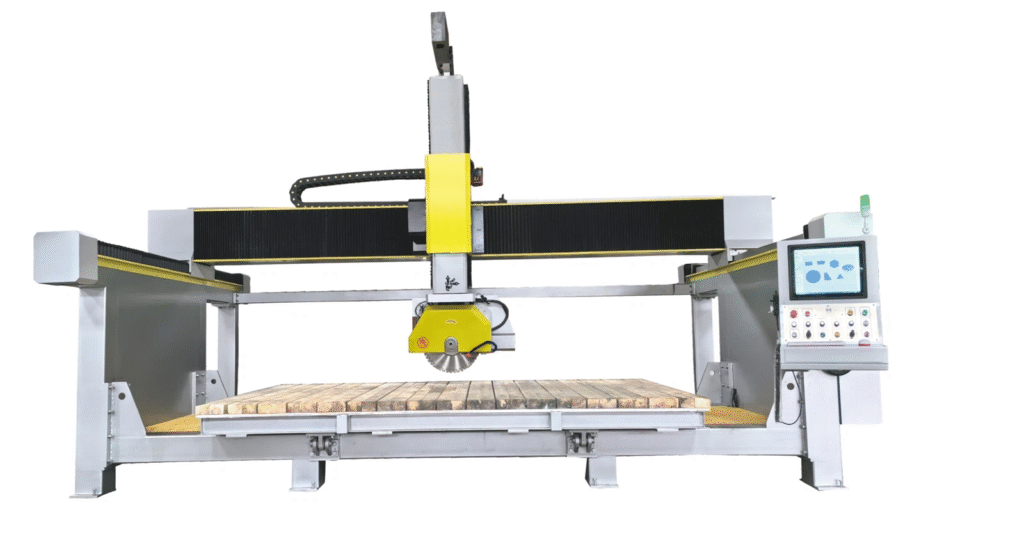

Classic Look:

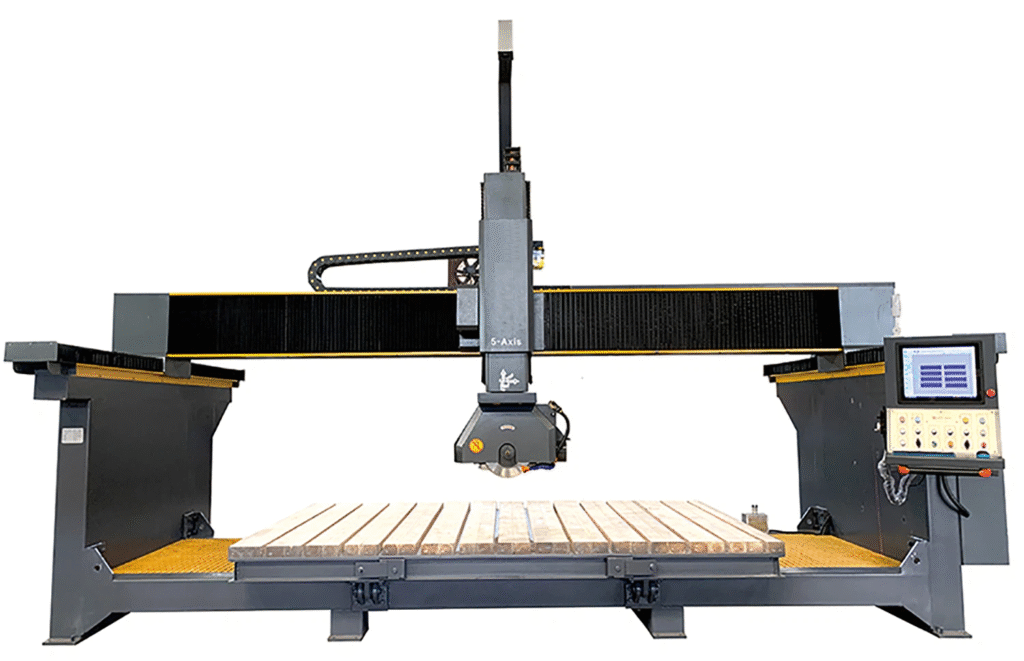

New Look:

1) Mono-block Structure with Man-Machine interaction(√)

(2) With An Electric spindle speed:24000rpm,Power: 5.5 kw/7.5kw(√)

(3) With A Camera, Photo layoutfunction(√)

(4) With Automatic measuring probe for thickness(√)

(5) With An automatic Tool Setting Gauge(√)

(6) With an industrial computer and a touch-screen.(√)

(7) With Suction Cups(√)

(8) With Auto Clamping system during Milling work(√)

(9) 22kw 5-axis special permanet magnet motor, which is 40% power saving.(√)

(10) With Automatic lubrication system (√)

(11) This Worktable can be Flipped over 85°, easy to load plate (√)

(12) Vein Matching Function(√)

(13) Software update for free(√)

(14) 600CNC/5+1 model improve the precision of machine manufacturing; With long light strip on two

side; Improve machine travel speed; High standard electricity protection as

Italian standard. (OEMfor Italianmachine company).

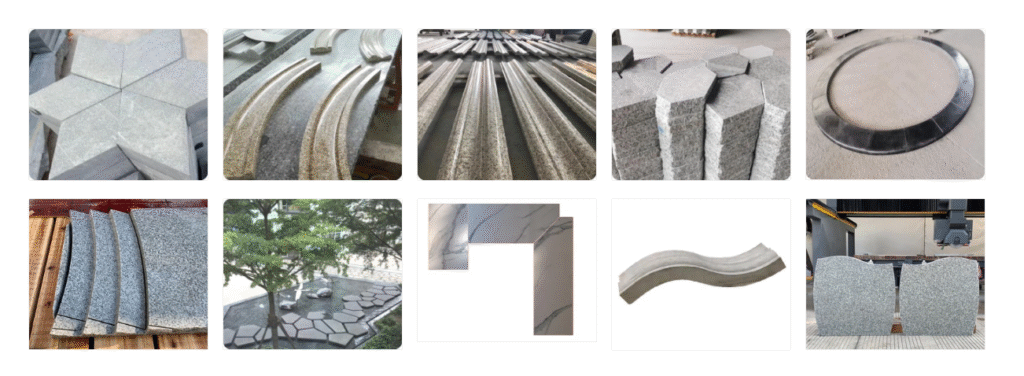

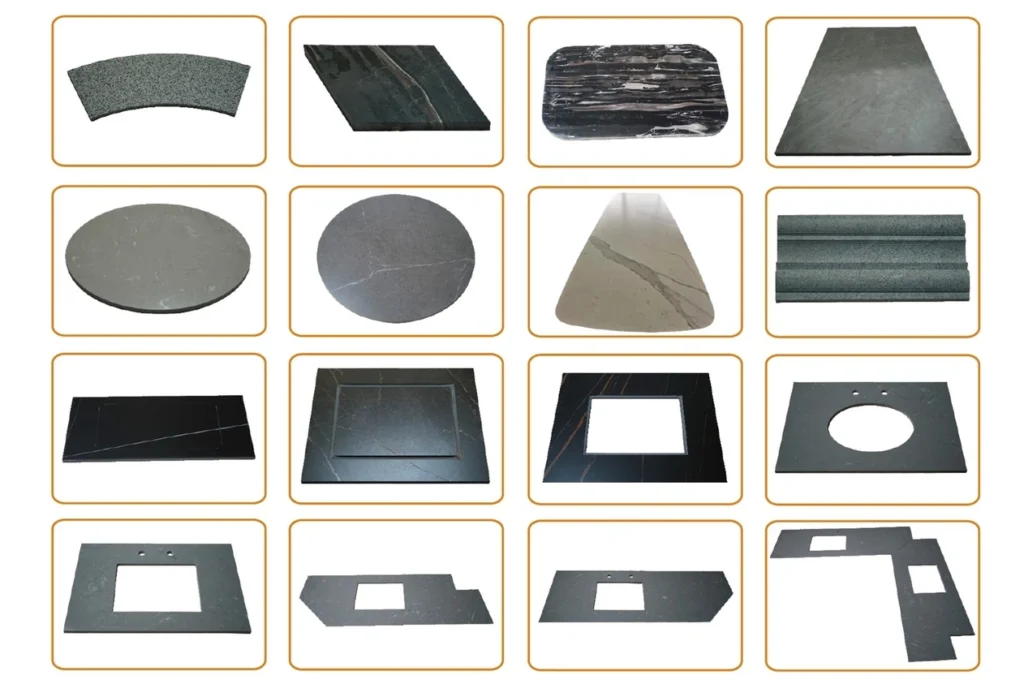

APPLICATIONS

- Bevel Cut, Straight Cut

- Cut various of shapes: Circle, Square, Rectangle…

- Line Shaping: Arc-Line Shaping, Straight-Line Shaping…

- Mill non-slip grooves, Slotting

- Sink Processing: drill faucet Holes, or mill inner corner for Kitchen sink(ZLBS-600CNC/5+1A)

- Concave-convex cut.