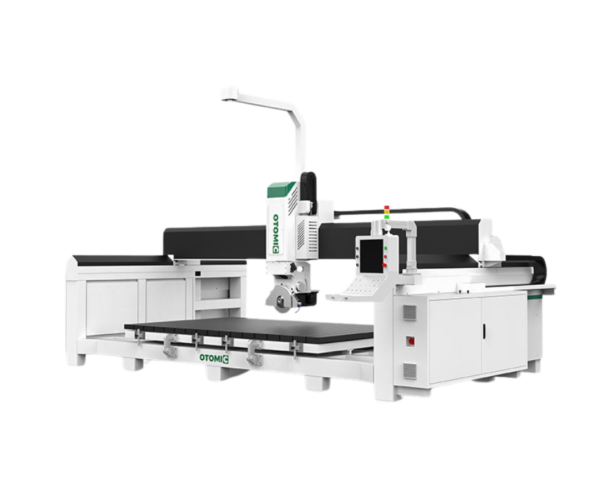

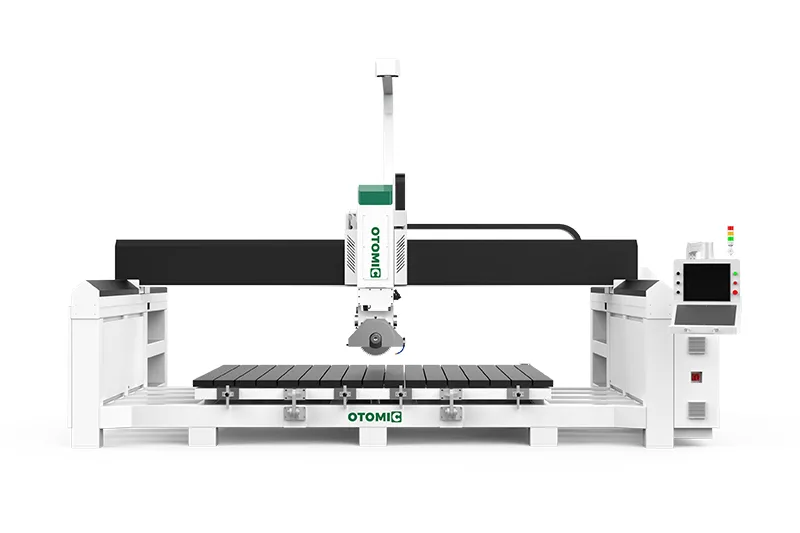

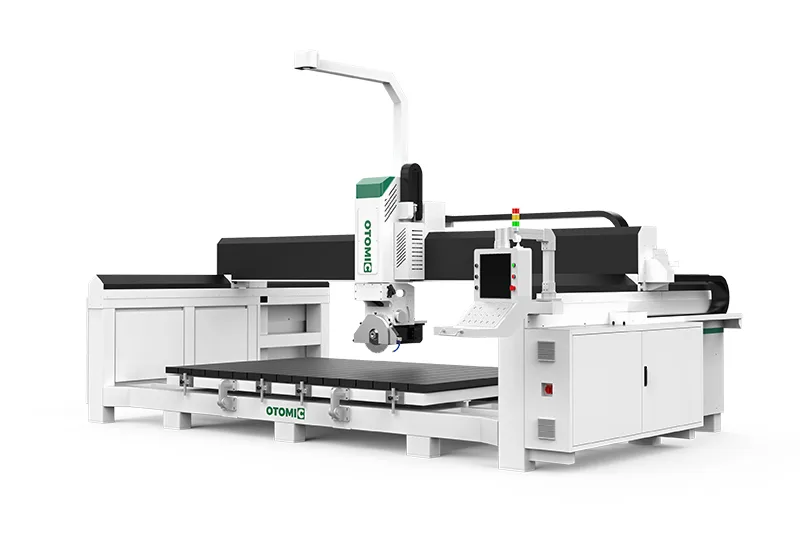

4 Axis CNC Granite Stone Cutting Machine Industrial for Slab Cutting

The 4 axis cnc bridge saw machine is a perfect cnc granite stone cutting machine for marble, and other types of stone slabs. With this tool, you can create beautiful countertops, kitchen tops, floors, and other stone surfaces that will last for years to come.

* Contact us for latest price for customized machine according to your project’s requirements of table formats, functions, etc.

Features

- One of the main features and advantages of using a 4 axis CNC granite stone cutting machine is that it can cut stones and other slabs with great precision.

- This means that the slab cuts are very accurate and smooth, which is important if you want to create high-quality products.

- Additionally, the 4 axis CNC granite stone cutting machine can be programmed to make different types of slab cuts, such as straight cuts, bevel cuts, and even curved cuts.

- This makes it a versatile tool that can be used for many different projects.

- Overall, if you’re looking for a reliable and efficient way to cut stone slabs or other materials, a 4 axis CNC bridge cutting saw is definitely worth considering.

Parameters

| Travel | 3 axis | To your projects |

| C axis | ±360° | |

| A axis | 0/45° | |

| Servo motor | X axis、Y axis | 2KW HANYU absolute value servo motor |

| Z axis | 2KW HANYU absolute value servo motor (with brake) | |

| C axis | 1KW HANYU absolute value servo motor | |

| Guide | Y axis | Taiwan 30# |

| X axis | Taiwan 30# | |

| Z axis | Taiwan 30# | |

| Rack | X axis、Y axis | 2M |

| Worktable | Structure | Squared timber |

| Table size | To your projects | |

| Flip angle | 0-85° | |

| Reverse weight | 800KG | |

| Saw blade | Size | 360mm |

| Maximum thickness | 60mm | |

| Screw | Z axis | 3210 |

| Reducer | X/Y axis SHIMPO reducer | |

| Saw blade motor | 15KW Saw blade motor (rated: 2930r/min) | |

| Inverter | 18.5KW Fuling inverter | |

| Controller | Blue Elephant customized control system(built-in CAM software) | |

| Low-voltage apparatus | Schneider | |

| Air pressure | 0.6-0.8Mpa | |

| Voltage | To your needs | |

| Bevel cuts | 45°, 90° | |

| Miter cuts | Any degree | |

| Curved cuts | Yes | |