Infrared Automatic PLC Bridge Cutter Machine

The HLSQ-450 stone bridge cutting machine is controlled by a PLC, the cutting dimensions are digitally input by a computer terminal, all operations can be done manually or automatically by a computer programme.

* Contact us for latest price for customized machine according to your project’s requirements of table formats, functions, etc.

Features

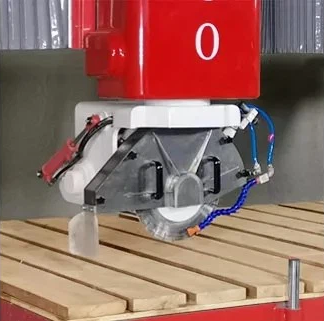

The infra-red automatic bridge cutter is a kind of stone plate cutting and processing equipment which is set on the base track for linear movement, driving the diamond circular saw blade, using infra-red for knife alignment to determine the size and straightness of the stone to be cut, and to ensure that the cutting track moves in a straight line. As the infrared automatic bridge machine is equipped with a single plate machine, the cutting of stone is completely automatic and controlled, only the required size can be entered to obtain the corresponding size of the plate.

It is the preferred equipment for processing plates in stone processing plants in recent years. In recent years, Hualong Stone Machinery Co., Ltd. has developed a model with adjustable head angle, which can cut beveled edges, double beveled edges, etc., greatly adapting to a variety of cutting requirements.

The HLSQ-450 stone bridge cutting machine is controlled by a PLC, the cutting dimensions are digitally input by a computer terminal, all operations can be done manually or automatically by a computer programme; the control panel is on the right hand side of the machine, which is convenient for the operator to adjust the machine when placing the plates; the panel has operating buttons, encoders and an LCD display.

The machine can be set up to 8 different cutting sizes at the same time, each size can be repeated up to The machine can be set to cut up to 8 different sizes at the same time, each size can be repeated up to 9999 times, and the cutting mode can be set to lower the knife in stages; equipped with an infrared knife setting instrument for accurate positioning; the cutting feed speed is adjusted by the frequency converter; the saw blade is driven directly by the motor, and can be driven by the hydraulic pressure, automatically rotating 90°; the maximum cutting capacity is 3200mm x 2000mm; the table can bear 600kg, and can be turned 0° to 85°. The support frame and the frame are integrated and can be quickly installed and used, easy to move, no need to lay concrete foundation in advance.

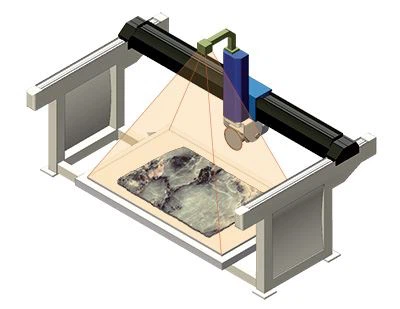

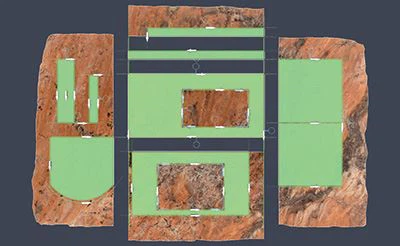

SLAB IMAGE CAPTURE

The application allows to acquire and process the slab photo, by correcting the lens distortion and rectifying it. Through the acquired image, the shapes can be arranged on the slab avoiding material imperfections while identifying the nervures that need to be machined; it is also possible to qualify the slab edge geometrically.

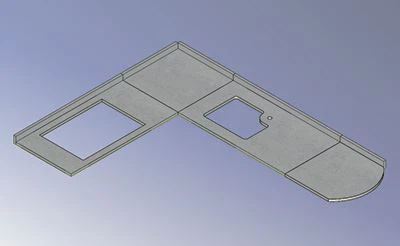

DRAWING AND DESIGN

It is possible to define the shapes being machined:with 2D CAD tools/by importing a DXF/DWG file

with the automatic acquisition from a photo (using the photo-digitizer module)by importing a list from a proprietary format: Excel, CSV

The shapes begin machined will be grouped in an itemized list.

SHAPES POSITIONING

The shapes can be arranged on the slab both with manual and automatic nesting. The shapes being nested are loaded from the active itemized list.

SOFTWARE FUNCTIONALITIES

Slab cutting handling

CAD 2D tools

Manual/automatic Nesting

Calculation of optimized trajectories for the disk cutting

Automatic rest machining to complete the cuts using a cut-drill/mill tool or a waterjet tool

Movement of the slab pieces through the suction cups manipulator.